Understanding aviation Maintenance, Repair, and Overhaul (MRO) goes beyond the technical basics; it requires a deep grasp of the financial complexities that drive every project bid and budget. With rising cost pressures and increasingly complex estimation challenges, MRO contractors need advanced tools to create accurate forecasts, control expenses, and stay competitive in a demanding market.

What is Aviation MRO?

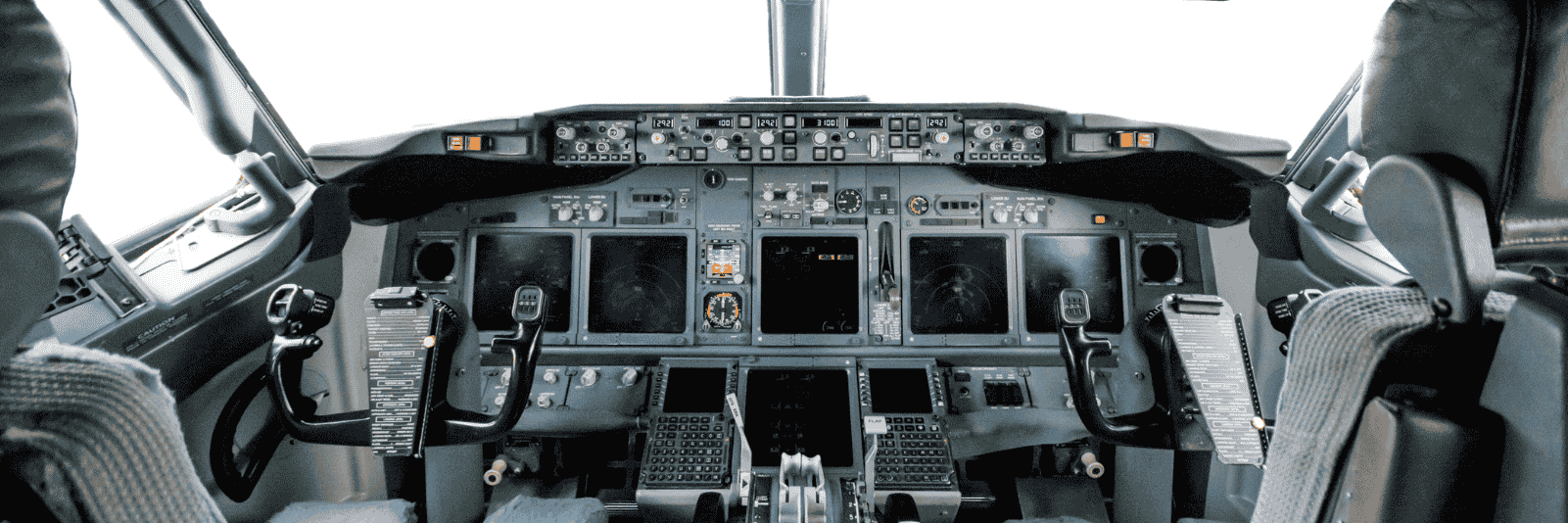

In aviation, Maintenance, Repair, and Overhaul (MRO) covers all the work needed to keep aircraft safe, reliable, and airworthy. This includes routine inspections and checks (A/B/C/D checks), troubleshooting and repairing faults, and even fully disassembling and rebuilding engines or structures to OEM standards. MRO keeps planes flying safely, extends an aircraft’s life, and ensures passenger safety.

Most MRO work must be performed by certified facilities or mechanics (FAA-certified repair stations), adhering to strict regulatory standards. Airlines, airframe manufacturers, and dedicated MRO providers all rely on these services to meet regulations and avoid costly flight disruptions.

The Top Cost Drivers and Project Cost Categories

In project management, costs are generally classified as fixed, variable, direct, indirect, and sunk. Direct costs are expenses tied to specific work (like labor and materials), indirect costs are overhead and support, fixed costs don’t vary with work volume (e.g. equipment rentals or fees), variable costs change with scope (e.g. fuel or consumables), and sunk costs are past expenditures (not usually included in new estimates). We’ll organize the top MRO cost drivers under these categories:

- Direct Costs are those you can directly link to the aircraft service itself. This includes the skilled labor, such as mechanics, avionics technicians, and inspectors, whose time is logged against the job; the parts and materials, including engines, avionics, and critical spares; the equipment and tooling, like engine stands or scaffolding rentals used during repairs; and subcontracted services, such as outsourcing non-destructive testing or composite repairs.

- Indirect Costs support the project but aren’t tied to a specific line item. Here you find administrative overhead, including project management, quality control, and compliance reviewers; and transportation and logistics, covering the handling, shipping, or special transport of aircraft or components—expenses not directly billed but essential to the project’s success.

- Fixed Costs remain the same regardless of the project’s scale or duration. In aircraft MRO, two big ones stand out: the hangar or bay rental, which is often a flat rate per day or per slot, and the aircraft downtime cost—the revenue an airline forfeits when a plane can’t fly because it’s in heavy maintenance.

- Variable costs fluctuate with the amount of work completed. This includes consumables and expendables, such as lubricants, sealants, fasteners, and cleaning supplies, which escalate with more tasks; and the contingency for unforeseen repairs, budgeted for surprise findings once maintenance begins.

- Sunk Costs are costs that have already been spent and shouldn’t influence your current estimate. These might include prior surveys, initial inspections, or preparatory work—all important historical expenditures but irrelevant when building your next bid.

| Project Cost Type | Top Cost Factors in Aviation MRO |

| Direct Costs | • Skilled labor (mechanics, avionics, inspectors) • Parts & materials (engines, avionics, spares) • Equipment & tooling (rental or maintenance) • Subcontracted services (e.g., NDT, painting, composite repair) |

| Indirect Costs | • Administrative overhead (project management, compliance, quality control) • Transportation & logistics (aircraft or parts movement, customs, handling fees) |

| Fixed Costs | • Hangar or bay rental fees • Aircraft downtime cost (loss of revenue during maintenance) |

| Variable Costs | •Consumables and expendables (lubricants, sealants, fasteners) •Contingency for unforeseen repairs or scope changes |

| Sunk Costs | Previous inspections, prior surveys, or preparatory work already expended |

Main Challenges MRO Contractors Face in Project Estimation

Building an accurate MRO bid is notoriously difficult. First, scope uncertainty is significant: many issues only become apparent once work begins. Old airframes often conceal corrosion or fatigue that becomes apparent during disassembly. Estimators must guess contingency work without grossly overpricing. Second, supply chain volatility throws wrenches into plans. Parts shortages or long lead times can derail schedules and inflate labor costs if crews sit idle. Material price spikes (as noted above) add another wrinkle. Third, regulatory complexity adds hidden tasks. MRO work in the U.S. must meet FAA/EASA certification rules, and may involve special environmental or safety procedures (e.g. engine run-ups, waste handling, inspection reports). Failing a compliance step can mean fines or rework, so these costs must be anticipated (just as marine MRO cites strict IMO/SOLAS rules

Finally, outdated tools and processes hamper accuracy. Too many shops still use spreadsheets, emails, and siloed rate cards to create quotes. This unstructured approach makes it easy to omit labor hours or markups and hard to reuse knowledge. When veteran estimators leave, their know-how often goes with them, leaving gaps that can cause costly mistakes down the line.

How OAE Helps Aviation-Based MRO

OAE’s cloud-based estimation platform is purpose-built to solve these problems. It lets senior estimators capture their hard-won knowledge in templates and libraries, so that best-practice rates, labor breakdowns, and workflows are stored consistently across all projects and teams.

Newer team members can use these libraries to build bids quickly without missing details, ensuring nothing falls through the cracks. OAE is designed for complex, multi-year projects (common in heavy maintenance) and handles change orders seamlessly. Access is permission-based, so you can even have outside shops enter their pieces of the estimate without exposing your full price book.

The aviation MRO industry faces unprecedented challenges in cost estimation and project management. With OAE, you gain the sophisticated tools needed to navigate this complex landscape successfully, win more contracts, and maintain the margins essential for sustainable growth.