MRO stands for Maintenance, Repair, and Operations. MRO inventory management is the set of processes, policies, and systems used to control the spare parts, consumables, tools, and supplies that keep equipment, facilities, and operations running. Unlike production inventory (raw materials and finished goods), MRO items are typically used to maintain uptime, safety, and regulatory compliance from bearings and filters to lubricants, fasteners, PPE and repairable components.

Types of MRO Projects

MRO projects encompass a variety of maintenance and operational activities tailored to ensure the reliability, safety, and efficiency of an organization’s equipment, facilities, and infrastructure.

- Preventive Maintenance Projects: These are proactive projects scheduled regularly to prevent equipment failure and extend asset lifespan. Tasks may include inspections, lubrication, replacements of worn parts, and system calibrations to maintain optimal performance and avoid unexpected breakdowns.

- Predictive Maintenace Projects: These projects use data, sensors, and analytics to predict when maintenance should occur based on actual equipment condition. This helps optimize maintenance timing, minimize downtime, and reduce unnecessary maintenance tasks.

- Corrective Maintenance Projects: Reactive projects that address equipment or system failures after they occur. Though essential for emergency repairs, these projects can lead to higher downtime and costs if not carefully managed.

- Infrastructure Maintenance Projects: Focused on maintaining physical facilities and infrastructure such as buildings, HVAC systems, plumbing, electrical systems, and safety installations to ensure safe and compliant operation of facilities.

- Production Equipment Maintenance Projects: Projects aimed at maintaining and servicing machinery, conveyors, pumps, motors, and other production-related equipment to prevent disruptions in manufacturing processes.

- Material Handling Equipment Maintenance: Projects for the upkeep of forklifts, conveyors, robotic arms, pallet jacks, and other equipment essential to moving materials efficiently within a facility.

- Tooling and Consumables Management: Projects ensuring the availability and upkeep of hand tools, power tools, consumables like lubricants, cleaning supplies, and safety equipment (PPE) to maintain operational readiness and worker safety.

- Testing and Compliance Projects: Activities related to the calibration, testing, and certification of equipment and instruments to comply with regulatory standards and ensure equipment accuracy.

Effective MRO inventory management is vital for ensuring that critical maintenance, repair, and operational supplies are always available when needed, preventing costly production downtime. It improves workflow efficiency by reducing the time spent searching for parts, while also controlling costs by avoiding both overstocking and emergency purchasing.

Properly managed MRO inventory supports safety compliance, enhances operational productivity, and ultimately contributes to customer satisfaction by enabling timely and uninterrupted maintenance activities.

What is MRO Inventory Management?

MRO inventory management is the systematic process of ordering, tracking, allocating, and replenishing supplies, tools, and equipment essential for Maintenance, Repair, and Operations (MRO) activities. MRO inventory refers to all the indirect materials, supplies, and equipment that organizations need to keep their facilities operational and production running smoothly, but which are not directly incorporated into the final products they sell.

MRO inventory management centers on items that support business continuity and operational efficiency. These items are critical for preventing downtime, maintaining equipment functionality, and ensuring safe working environments across various industries.

Complex Industries that Rely on MRO

MRO inventory management is essential across numerous industries, each with specific requirements and challenges:

| Industry | Description |

| Manufacturing | – Regular maintenance of assembly line machines – Replacement of worn bearings and conveyor belts – Upkeep of production equipment to minimize downtime |

| Energy | – Repairs and turbine maintenance – Equipment monitoring for safety and reliability – Compliance with regulatory standards |

| Infrastructure and Utilities | – Maintenance of physical structures including roofing, doors, and windows – Upkeep of critical systems like HVAC, electrical, plumbing, and lighting – Repair and management of public infrastructure such as transportation hubs and utilities – Ensuring operational safety and minimizing downtime through scheduled and emergency repairs |

| Maritime | – Vessel maintenance and engine overhauls – Navigation system repairs – Port facility upkeep to ensure operational efficiency |

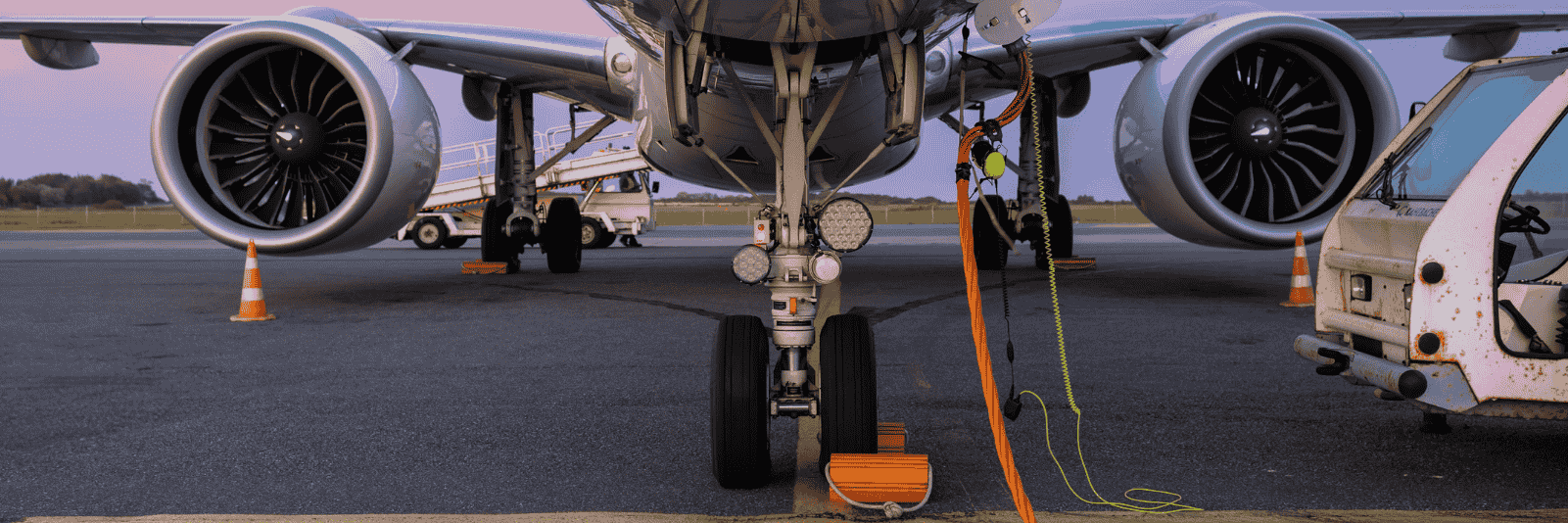

| Aviation | – Scheduled aircraft inspections and engine overhauls – Repairs adhering to strict regulatory maintenance standards – Ensuring airworthiness and operational readiness |

| Government and Defense | – Maintenance and modernization of military vehicles and weapons systems – Repairs and upkeep of defense infrastructure and base facilities – Support for public government agencies including federal buildings, prisons, and aviation – Management of large-scale MRO programs to reduce costs and improve operational readiness |

Key Components of MRO Inventory Management

Effective MRO inventory management involves several interconnected components that ensure optimal resource utilization and operational continuity:

- Procurement and Vendor Management: Strategic sourcing involves establishing long-term supplier relationships, negotiating favorable contracts, and implementing vendor-managed inventory (VMI) programs to reduce lead times and administrative burden.

- Storage and Organization: Efficient storage systems include organized warehouses with proper labeling, bin locations, barcode scanning for accuracy, and both centralized and distributed stockrooms based on operational needs.

- Inventory Tracking and Control: Advanced tracking mechanisms include real-time inventory monitoring, automated reorder points, cycle counting procedures, and comprehensive reporting to stakeholders about inventory status and consumption patterns.

- Demand Forecasting and Planning: Data-driven forecasting uses historical consumption data, maintenance schedules, and predictive analytics to anticipate future needs and optimize stock levels.

Challenges in MRO Inventory Management

Organizations face numerous challenges when managing MRO inventory, which can significantly impact operational efficiency and costs:

- Inventory Imbalances: Overstocking ties up valuable capital and consumes storage space, while stockouts lead to costly downtime and emergency purchases at premium prices.

- Data Quality and Visibility Issues: Poor data quality, incomplete records, and lack of system integration make it difficult to track actual stock levels and analyze consumption patterns effectively.

- Fragmented Procurement Processes: Decentralized purchasing, reactive procurement, and lack of standardized procedures result in inefficient spending and missed cost-saving opportunities

- Demand Unpredictability: Unlike production inventory, MRO demand is often irregular and difficult to forecast, leading to challenges in setting appropriate stock levels and reorder points

- Supply Chain Complexity: Managing extensive vendor networks, dealing with long lead times, and coordinating multiple suppliers can create bottlenecks and increase procurement costs.

- Obsolescence Management: Identifying and managing outdated inventory becomes difficult when items are stored in less accessible locations, leading to unnecessary carrying costs

- Lack of Standardization: The wide variety of MRO items and absence of standardized processes make inventory management complex and prone to errors.

How OAE Can Help with MRO Inventory Management

OAE can significantly enhance MRO inventory management by providing comprehensive resource planning and tracking capabilities that integrate MRO components directly into project workflows. Its Assembly feature supports the creation of standardized, reusable inventory components, streamlining ordering and replenishment processes.

Real-time collaboration and visibility help prevent stockouts and overstocking, ensuring supplies are available when needed without excessive carrying costs. OAE’s rate cards and cost management tools offer precise tracking of MRO item costs, aiding in budgeting and procurement decisions. Additionally, OAE’s secure file management allows organizations to keep maintenance specifications and procurement documents organized and accessible.

By leveraging historical project data and custom properties, OAE enables better demand forecasting and inventory optimization, making MRO inventory management more proactive, efficient, and aligned with operational goals. This integrated approach reduces downtime, controls costs, and supports regulatory compliance, helping organizations maintain smooth, cost-effective maintenance operations.