In industries where precision and performance matter, from shipbuilding and aviation to MRO and government contracting, procurement isn’t just buying supplies. It’s a strategic function that shapes budgets, risk profiles, and competitive outcomes. Accurate procurement cost assessment is central to ensuring projects stay on schedule, within budget, and compliant with industry and regulatory expectations.

Understanding Procurement in Complex Projects

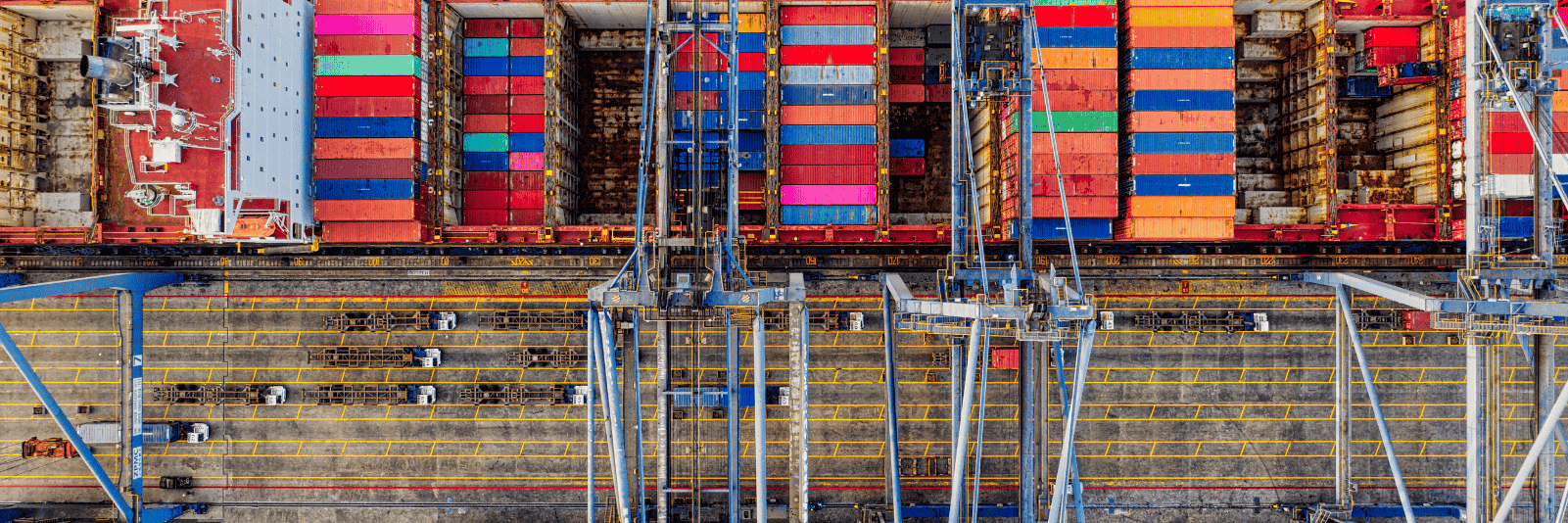

Procurement in complex industries is far more than purchasing. It’s the orchestrated acquisition of materials, labor, services, equipment, and specialized expertise needed to deliver a project from conception through delivery, and often beyond. In shipbuilding, it might mean coordinating thousands of unique parts from dozens of suppliers across multiple countries and calendar years. In aviation maintenance, it means securing hard-to-source components while managing inventory obsolescence and regulatory compliance. In government contracting, it means navigating strict regulatory requirements while maintaining cost predictability.

The complexity arises from several key challenges:

Multilayered supply chains: Most complex projects require assemblies that themselves require sub-assemblies, each with different lead times, quality requirements, and supplier economics. A single naval ship procurement might involve first-tier integration contractors, hundreds of second-tier specialized suppliers, and thousands of third-tier material and component providers.

Regulatory constraints: Industries like aviation and defense operate under strict certifications (FAA, CMMC, ITAR, NIST compliance). These requirements drive procurement costs upward because they limit supplier options, mandate traceability, increase documentation, and often preclude the lowest-cost global options in favor of approved or domestic suppliers.

Variability and uncertainty: Unlike mass-market procurement, complex project procurement deals with unique specifications, evolving requirements, and long lead times. A design change made in month 8 of a 24-month program can cascade into supplier renegotiations, expedited charges, and margin erosion.

Lifecycle economics: In aviation and maritime, the true cost of procurement is not the purchase price but the total cost of ownership, including installation, maintenance, spare parts availability, training, and eventual decommissioning. Procurement decisions made today affect operational costs for years.

The Top Cost Drivers in Procurement for Complex Industries

Maritime and Shipbuilding Procurement Cost Drivers

| Cost Driver | Examples | Impact | Mitigation Strategies |

| Logistics and Freight Costs | Red Sea/Panama disruptions → $500-1,500/container surcharges | Non-negotiable pass-throughs on global component sourcing | Regional supplier networks, bulk ocean freight |

| Raw Material Volatility | Steel/aluminum prices tied to China demand, geopolitical events | Unpredictable pricing erodes bid margins during multi-year builds | Long-term material contracts, hedging |

| Labor Cost Inflation | Skilled welder/pipefitter shortages | Wage pressure + overtime premiums during peak construction | Automation, modular construction |

| Design Phase Cost Lock-in | 80-90% of costs determined during initial design | Legacy designs/supplier solutions lock in excess costs across 1000s of parts | Should-cost analysis, design-to-cost |

Aerospace and Aviation

| Cost Driver | Examples | Impact | Mitigation Strategies |

| Supply Chain Backlog | Lead times are doubled due to aircraft parts backlog | OEMs report disruptions; component shortages cascade to airlines | Lead times are doubled due to the aircraft parts backlog |

| Aging Fleet Maintenance | Older aircraft kept flying due to new deliveries delays | More frequent/expensive MRO leads additional maintenance costs | More frequent/expensive MRO leads to additional maintenance costs |

| Engine Leasing Costs | Extended maintenance downtime due to part shortages can extend leasing periods to keep the fleet operational | Added cost on engine leasing due to extended lease periods | Engine pooling programs, predictive maintenance |

| Fuel Cost Escalation | Less efficient older fleet burns more fuel | Direct procurement impact through fuel hedging contracts | The less efficient older fleet burns more fuel |

| Inventory Holding Costs | More frequent/expensive MRO leads to additional maintenance costs | Larger holding stocks can lead to capital being tied up. | Vendor-managed inventory |

Key Cross-Industry Cost Drivers

Beyond the industry-specific factors, several universal cost drivers affect all complex procurement operations:

- Manual Processes and Data Entry Errors: Manual estimation and procurement processes introduce significant hidden costs. When organizations rely on spreadsheets and disconnected systems, they face increased time requirements, higher error rates, and difficulty in capturing institutional knowledge. A single data entry mistake in a multi-million dollar bid can prove catastrophic.

- Supplier Relationship Management: Poor supplier relationships cause businesses to face inconsistent communication, missed opportunities for collaboration, and limited leverage in negotiations. Understanding supplier cost drivers and market trends is essential for mitigating inflation risks and building resilient supply chains.

- Knowledge Management Failures: The biggest threat to growing organizations is senior estimator knowledge walking out the door without being captured for reuse. Decades of expertise are lost when not systematically documented and made accessible to future teams.

- Subcontracting Complexity: Managing subcontractor networks, ensuring quality control, and coordinating multiple parties adds layers of complexity and cost to procurement. Issues with subcontracting limits correlate directly with increased overall program costs.

Best Practices in Streamlining Procurement Costs

Organizations that excel at procurement cost management implement systematic approaches that address the root causes of inefficiency. Here are proven strategies for optimization:

Implement Strategic Sourcing

Move beyond transactional procurement toward strategic partnerships. Strategic sourcing practices reduce costs and improve efficiency compared to transactional procurement. This means evaluating suppliers based on total value rather than just unit price, considering factors like quality, reliability, and innovation potential.

- Conduct a comprehensive spend analysis to identify your highest-value procurement categories

- Develop category-specific strategies that align with organizational goals

- Build long-term relationships with strategic suppliers rather than constantly switching vendors

Leverage Technology and Automation

Anomaly detection flags unusual spending patterns in real time, such as suppliers charging significantly more than last quarter or purchases that violate procurement policies. Modern procurement platforms enable organizations to catch issues before they become expensive problems.

Automated workflows handle routine purchase requests without manual intervention, freeing procurement professionals to focus on strategic decisions.

Establish a Credible Should-Cost Baseline

Should-cost analysis determines what a product, service, or assembly should cost based on materials, labor, overhead, and a reasonable profit margin. It is fundamentally different from supplier quoting; it establishes an independent benchmark that validates, challenges, or informs supplier pricing discussions.

In defense procurement, should-cost analysis is embedded in FAR practices. Leading commercial organizations, including companies in aerospace, maritime, and MRO, have adopted a should-cost discipline with measurable results.

How to Implement: Break down each procurement package into its cost components (materials, labor, overhead, logistics, quality, profit). Use historical data from completed projects, industry benchmarks, and supplier inputs to build a defensible model. Present should-cost not as a “price target” but as a fact-based reference point for negotiation. The gap between should-cost and supplier quote often reveals inefficiencies worth discussing, whether excessive supplier markup, inefficient production methods, or unrealistic assumptions.

Impact: Organizations that systematize should-cost achieve 10–15% cost savings through improved supplier negotiations and more effective category management.

Front-Load Project Definition and Scope Clarity

Cost estimation accuracy improves dramatically when scope, design, and assumptions are locked early. Best-practice guidance recommends investing 3–5% of the total project cost in front-end definition before procurement begins.

This principle applies across industries. In shipbuilding, 80–90% of costs are determined during design. In contracting projects, a mature design and clear statement of work are prerequisites for accurate cost estimation and bid success.

How to Implement: Use multi-disciplinary teams (engineering, procurement, operations) to define scope, identify key assumptions, and surface risks before RFQs are released. Create a detailed assumptions register, document engineering assumptions (constructability, specs, design choices), commercial assumptions (supplier landscape, lead times, market conditions), and execution assumptions (schedule, risk allocation, logistics).

Impact: Front-end loading delays project start by weeks, but recovers that time many times over through fewer change orders, supplier disputes, and cost surprises during execution.

Consolidate Supplier Base

Fragmented procurement, buying from many small suppliers with limited volume leverage, is a common cost driver, particularly in MRO and distributed operations.

Supplier consolidation creates several benefits

- Volume Leverage: Bundling purchases of like components across programs creates negotiating power.

- Reduced administrative burden: Managing 50 suppliers is more efficient than managing 200. Fewer vendors mean streamlined compliance checks, better communication, and faster problem resolution.

- Visibility and control: A smaller, rationalized vendor base makes it easier to monitor pricing trends, spot opportunities, and ensure compliance with specifications

How to implement: Conduct a comprehensive spend analysis to identify overlapping and redundant suppliers. Evaluate the total cost of ownership, not just unit price, when deciding which suppliers to consolidate around. Use category management to group similar products and develop tailored sourcing strategies for each category.

Impact: Category management combined with supplier consolidation generates 10–15% cost savings while improving supply chain resilience.

Shift from Time-and-Material to Outcome-Based Contracting

This principle is particularly applicable to MRO and service-based procurement. Traditional time-and-material contracts incentivize higher labor hours and longer service durations. Outcome-based or uptime-based contracts align supplier incentives with customer objectives.

How to implement: For critical maintenance services, negotiate contracts based on equipment uptime, mean-time-between-failures, or other performance metrics. Include incentive clauses for exceeding targets and penalties for underperformance. Combine full-service contracts with extended warranties to shift risk to the service provider.

Impact: Organizations shifting from time-and-material to outcome-based MRO contracts report 15–25% cost savings while improving asset reliability.

Adopt Total Cost of Ownership (TCO) Thinking

Unit price is seductive but misleading. A cheaper component that requires frequent maintenance, has short service life, or creates supply chain complexity may cost far more over its lifecycle than a pricier alternative.

How to implement: For major procurement decisions, build a TCO model that includes:

- Acquisition cost

- Installation and integration cost

- Maintenance and spare parts cost

- Downtime risk and impact

- Training and support cost

- Compliance and regulatory cost

- Obsolescence and end-of-life cost

Use TCO to compare suppliers and options objectively. A supplier quoting 5% higher unit price but offering superior reliability, lower maintenance, and better supply chain stability may deliver 20% lower TCO.

Impact: TCO thinking shifts procurement conversations from “how cheap?” to “what’s the best long-term value?” and often reveals counterintuitive cost savings.

Establish Clear Governance and Accountability

Cost estimation and procurement decisions carry significant financial risk. Yet ownership is often diffuse: estimators build the forecast, procurement executes, project leaders accept the results, and when overruns occur, blame is spread.

Best practice establishes clear ownership and accountability:

- Senior leadership sign-off: The Project Director and Senior Responsible Owner (SRO) must understand and formally accept the cost estimate, including its assumptions, risks, and contingencies.

- Independent review: Internal reviewers and external assurance validate methodology, data quality, and assumptions.

- Cost estimate as performance metric: Track actual costs against estimated costs and use variance analysis to improve future estimates.

- Continuous improvement: Capture lessons learned and benchmark data from completed projects to refine estimation methodologies.

How to implement: Establish a cost governance framework early in the project. Assign clear roles: who estimates, who validates, who approves, who monitors. Use stage-gate reviews to validate estimates before major procurement commitments.

Impact: Clear governance reduces cost overrun rates and builds organizational learning that improves estimation accuracy over time.

How OAE App Can Help Streamline Procurement Cost Assessment

OAE App is purpose-built for the estimation and procurement challenges of capital-intensive industries. The platform addresses the core pain points of complex procurement:

Expert Knowledge Capture: Organizations can build libraries of proven bids, standard rate cards, and component calculators. Rather than starting from scratch on each new project, teams leverage institutional knowledge, improving both speed and consistency.

Multi-Level BOM Management: Complex projects involve thousands of components and assemblies organized hierarchically. OAE enables teams to manage this complexity while maintaining traceability and controlling detail.

Real-Time Collaboration: Distributed teams working on the same estimate can collaborate live, assigning owners, tracking changes, and resolving inconsistencies in real time. This eliminates version control chaos and reduces errors.

Margin Optimization: Multiple rate card configurations enable teams to model different pricing scenarios, identify cost drivers, and optimize profitability. Teams can quickly test “what-if” scenarios to understand sensitivity to labor rates, material costs, or schedule assumptions.

Rapid Data Integration: Rather than transcribing historical data from spreadsheets, OAE enables import of prior estimates and copying of successful templates. This accelerates estimation and reduces data entry errors.

Multi-Year Project Support: Capabilities for managing projects spanning multiple years with period-specific cost structures, labor rates, and assumptions ensure accuracy across long, complex programs.

Zero-Click Refresh Real-Time Updates: As team members enter data or modify assumptions, the estimate updates automatically, allowing everyone to see margin changes and progress in real time.

Compliance and Security: NIST, CMMC, and ITAR compliance, combined with flexible deployment options (cloud or on-premise), ensure that government contractors and defense suppliers can maintain security and auditability.

Procurement cost assessment in complex projects is part art, part science. Success requires discipline in estimation methodology, transparency in supplier negotiations, and accountability in execution. Organizations that master procurement cost management don’t simply win more bids, they win more profitable bids, maintain healthier margins, and build competitive advantage through operational excellence.

The best practices outlined here, should-cost analysis, front-end loading, supplier consolidation, outcome-based contracting, TCO thinking, automation, and clear governance, are proven across industries. When combined with specialized tools like OAE that enable rigorous estimation and collaboration, these practices transform procurement from a cost center into a strategic advantage.