Shipbuilding projects involve complex phases in which costs can quickly escalate, thereby impacting profitability. Accurate estimation and streamlined processes are key to controlling these expenses and securing competitive bids.

For project owners, shipyards, and stakeholders alike, understanding where the money goes and how to control it can be the difference between profitability and costly overruns.

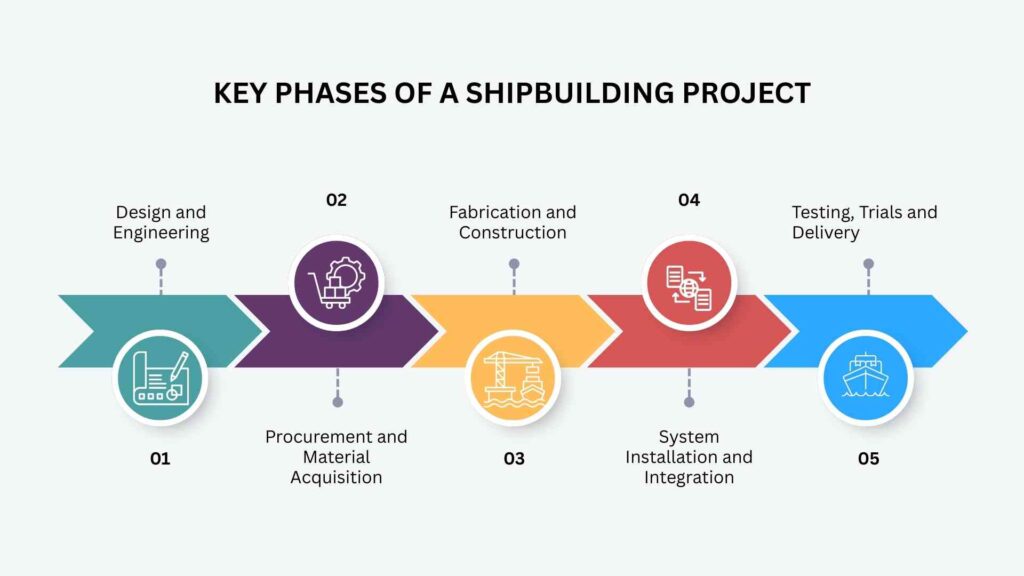

The Phases of a Shipbuilding Project and Their Cost Implications

Every shipbuilding project generally flows through several major phases. Each stage carries its own cost profile and risk dynamics:

Design and Engineering

This is the conceptual and planning stage. Detailed naval architecture, systems integration planning, regulatory compliance assessment, and prototype modeling all happen here.

Cost Drivers:

- Complexity of design (e.g., specialized naval systems vs. standard commercial hulls)

- Engineering hours and technical expertise

- Changes due to later alterations or discovery of feasibility gaps

Impact on Budget: A poorly scoped design increases rework costs downstream and magnifies risk across every subsequent activity.

Procurement and Material Acquisition

Once plans are finalized, critical materials and components are sourced, which involves sourcing everything from steel plates and propulsion systems to electronics and interior fittings. Material costs alone can account for a substantial portion of the total budget, and procurement timing significantly impacts cash flow management.

Cost Drivers:

- Material marketing pricing (steel, electronics, exotic alloys)

- Logistics and import duties

- Supplier reliability and lead times

Impact on Budget: Delays in procurement or price spikes in key commodities directly affect cash flow and schedule fidelity

Fabrication and Construction

This phase represents the most visible phase, where hull sections are fabricated, assembled, and outfitted with machinery, piping, electrical systems, and accommodations. Labor costs peak during this phase, and production efficiency directly impacts the bottom line.

Cost Drivers:

- Labor costs and productivity

- Shop infrastructure and equipment utilization

- Waste and rework due to poor planning or errors

Impact on Budget: This phase often consumes the majority of the budget and schedule. Inefficiencies here cascade into delays and cost growth.

System Installation and Integration

This represents the most visible phase, where hull sections are fabricated, assembled, and outfitted with machinery, piping, electrical systems, and accommodations. Labor costs peak during this phase, and production efficiency directly impacts the bottom line.

Cost Drivers:

- Complexity of electrical/hydraulic systems

- Integration challenges between subsystems

- Testing and commissioning requirements

Impact on Budget: Integration issues often surface late and trigger expensive fixes if they were not anticipated

Testing, Trials and Delivery

This phase ensures the vessel meets all specifications and regulatory requirements through sea trials, system testing, and final adjustments before handover to the owner.

Cost Drivers:

- Trial duration and resource allocation

- Corrections from trial feedback

- Compliance certification costs

Impact on Budget: Unexpected performance shortfalls can push costs dramatically higher at a point where budgets are already tight.

Major Cost Drivers That Can Impact a Shipbuilding Project

| Cost Driver | Description |

| Steel and Raw Materials | Raw materials form the bedrock of shipbuilding expenses. Steel prices fluctuate based on global market conditions, and a large commercial vessel can require thousands of tons. Beyond steel, modern ships incorporate aluminum for superstructures, specialized alloys for critical components, and composite materials for weight-sensitive applications. Exchange rate variations can significantly impact material costs when sourcing internationally, creating budgetary uncertainty that extends throughout the project timeline. |

| Labor | Skilled labor represents one of the most significant and least predictable cost factors. Shipbuilding requires diverse expertise, welders, pipefitters, electricians, painters, and specialized tradespeople. Labor costs vary dramatically by geographic location, and skilled worker shortages can drive up wages or extend schedules. Productivity rates directly influence labor costs, with experienced teams delivering substantially better cost performance than those learning new vessel types or technologies. |

| System Integration Complexity | Modern vessels are floating networks of interconnected systems that must operate reliably in harsh marine environments. The integration of mechanical, electrical, hydraulic, and electronic systems creates coordination challenges that can significantly impact costs. When systems from different vendors must interface, compatibility issues often emerge during installation, requiring engineering time, custom adapters, or even equipment replacement. The complexity multiplies with vessel sophistication, specialized vessels like research ships or cruise liners involve far more intricate system integration than basic cargo carriers. |

| Design Changes and Engineering Revisions | Every change order during construction triggers a cascade of costs. A seemingly minor design modification might require reworking already-fabricated components, revising documentation, reordering materials, and disrupting the production schedule. Late-stage changes prove particularly expensive, as they can necessitate cutting out completed work and affect multiple interconnected systems. |

| Equipment and Propulsion Systems | Main engines, generators, propulsion equipment, and navigational systems represent major capital expenditures. These items often have long lead times, and delays in delivery can idle construction teams and extend the project timeline. The choice between standard equipment and customized solutions significantly impacts both initial costs and long-term maintenance expenses. |

| Regulatory Compliance and Classification | Meeting international maritime regulations, classification society requirements, and flag state standards adds layers of cost through specialized inspections, testing, documentation, and potentially more expensive materials or construction methods. Environmental regulations particularly drive costs upward through requirements for emissions control systems, ballast water treatment, and fuel efficiency measures. |

| Schedule Overruns | Time is money in shipbuilding, and schedule delays multiply costs exponentially. Extended construction periods increase labor costs, facility overhead, financing charges, and opportunity costs. Weather disruptions, supply chain problems, workforce issues, or technical challenges can push completion dates back by months, devastating project profitability. |

How Cost Overruns Devastate the Bottomline

The financial impact of poor cost control extends far beyond simple budget exceedances. For shipyards, cost overruns on fixed-price contracts can transform profitable projects into money-losing ventures. When actual costs exceed estimates by even moderate percentages, profit margins evaporate entirely.

Cash flow suffers as unexpected expenses accelerate, potentially creating liquidity problems that affect other projects or operations. Reputation damage from cost and schedule overruns makes winning future contracts more difficult and may force yards to accept lower margins to remain competitive.

For vessel owners, construction cost increases may necessitate additional financing, reducing return on investment and potentially making the vessel economically unviable for its intended service. In competitive shipping markets, even small cost disadvantages can mean the difference between profitable operations and financial struggle.

Streamlining Cost Through Technology and Process Optimization

A successful shipbuilding project begins with realistic, comprehensive cost estimates that account for all major variables and include appropriate contingencies for uncertainty. Accurate projection enables better decision-making at every stage, from initial bidding through construction planning and change order evaluation.

Modern cost estimation moves beyond simple percentage markups on material and labor to incorporate historical data analysis, risk assessment, and scenario modeling. This approach identifies potential problem areas before they impact the schedule or budget, allowing proactive mitigation strategies.

Forward-thinking shipyards increasingly leverage technology to improve cost performance. Digital design tools reduce engineering hours and minimize errors that lead to costly rework. Production planning software optimizes material usage and construction sequencing, reducing waste and improving labor productivity.

Supply chain management systems provide visibility into material costs and delivery schedules, enabling better procurement decisions and reducing inventory carrying costs. Real-time project tracking allows managers to identify cost variances early when corrective action is most effective and least expensive.

How OAE Streamlines Cost Management

OAE App addresses the fundamental challenges shipbuilders face in cost estimation and project bidding through purpose-built tools designed for maritime construction complexity.

Comprehensive Cost Libraries within OAE App provide detailed breakdowns of labor, materials, and equipment costs specific to shipbuilding activities. Rather than starting from scratch or relying on outdated spreadsheets, estimators access current, validated cost data that reflects real-world conditions across all phases—from initial design through system integration and commissioning.

Parametric Estimation Capabilities allow rapid cost modeling based on vessel characteristics like size, type, complexity, and intended service. This enables quick feasibility assessments and “what-if” analyses that help teams understand cost implications of design alternatives before committing to detailed engineering.

Historical Data Integration leverages past project performance to improve future estimates. OAE App helps organizations capture lessons learned and actual cost data from completed projects, creating increasingly accurate estimates as the database grows. This is particularly valuable for the system installation and integration phase, where historical productivity data can reveal how long it actually takes to install and connect complex machinery and electrical systems.

Phase-Specific Cost Tracking allows project managers to monitor expenditures against budgets for each phase of the shipbuilding lifecycle. By understanding where costs accumulate during conceptual design, engineering, procurement, construction, system installation, and commissioning, teams can intervene early when variances emerge rather than discovering overruns at project completion.

System Integration Cost Modeling helps estimators account for the unique challenges of the installation and integration phase. OAE App can track labor requirements for different system types, coordination costs between trades, and the time required for testing and troubleshooting integrated systems, factors that are often underestimated in traditional estimation approaches.

Streamlined Bid Preparation transforms the traditionally labor-intensive proposal process. Rather than spending weeks compiling estimates from multiple sources and formats, teams use OAE App to generate comprehensive, professional bid packages in significantly less time. This efficiency allows estimators to focus on accuracy and competitiveness rather than mechanical data assembly.

Collaboration Features ensure all stakeholders work from a single source of truth. Engineering, procurement, production, and finance teams access the same cost data and assumptions, eliminating the miscommunications that often lead to budget problems. During system installation, when electricians, pipefitters, HVAC technicians, and automation specialists must coordinate closely, this shared visibility becomes even more critical.

Scenario Analysis Tools let estimators quickly model different construction approaches, material choices, or schedule options, identifying the most cost-effective path forward before committing resources. For example, teams can evaluate whether to install systems modularly before hull sections are joined or to install them after assembly—each approach carries different cost and schedule implications.

In shipbuilding, costs are everywhere, but unmanaged costs are avoidable. Understanding the major cost drivers in each project phase and adopting tools that bring visibility, consistency, and collaboration can transform risk into predictability.