Accurate cost proposals are mission-critical in the maritime industry. In shipbuilding, repair, or refit work, proposal estimation means translating every requirement, labor, material, overhead, and risk into a complete, detailed bid. The strength of your estimate can determine whether you win a contract or risk leaving money on the table.

With OAE, shipyard contractors can turn deep industry expertise into competitive, data-driven quotes. OAE’s platform consolidates all work items, labor rates, material costs, and risk components onto a single, live dashboard. This provides real-time cost visibility for your whole team, helping you bid with confidence and safeguard your profit margins

Creating Proposals for Maritime Projects

Proposal estimation is a strategic process of forecasting all costs, including labor, materials, overhead, compliance, subcontractors, and contingencies, associated with delivering a maritime shipyard project. It’s your blueprint for building a defensible, profitable bid. A strong estimate balances competitive pricing with margin protection, avoids surprises, and builds trust with stakeholders.

For shipbuilders and repair yards, this means listing every task in a refit or overhaul and assigning labor hours, material quantities, equipment, and markup. Each estimate must be thorough (missing an item can mean a hidden loss) and accurate (overpricing can lose the bid). OAE’s platform automates much of this because it doubles as a proposal estimation and CRM platform, supporting forecasting and planning. In practice, estimators create or import a work breakdown (e.g., welding, painting, engine overhaul) and OAE applies standard calculators and rate cards to each line. This structured approach captures senior estimators’ expertise in a reusable template. The end result is a proposal that meets customer specs and is backed by solid data, not just guesswork.

Key Challenges in Maritime Shipyard Estimation

Estimating ship repair, refit, or construction work involves special hurdles not found in simpler projects. Key challenges include:

- Variable and Complex Scope: Ships are highly customized. Repairs often uncover unexpected corrosion or damage. Large naval refits and multi-year overhauls involve changing requirements and complex government specifications. Even the U.S. Navy admits there are “uncertainties inherent in the estimating process and the volatile pricing of key materials,” which can dramatically inflate budgets.

- Regulatory Compliance: Naval and commercial bids demand strict formats and documentation. Missing a safety spec or technical certification can disqualify a bid outright. Estimators must ensure every contract clause and reporting requirement is addressed.

- Outdated Tools and Errors: Many yards still rely on Excel. Manual spreadsheets and emails lead to data silos and version conflicts. Without real-time collaboration, different people may edit outdated copies, causing costly omissions or miscalculations.

- Long Timelines and Inflation: Ship projects can span months or years. Estimators must forecast labor rates and materials (steel, electronics, fuel) that can change mid-project. Managing escalation and scheduling over long periods is tough with static tools.

- Knowledge Retention: Veteran estimators carry deep institutional knowledge. But if that expertise isn’t captured, a retiree’s insight is lost. Without a central system, each new estimator must reinvent the wheel, slowing bidding and risking inconsistency.

- Data Aggregation: A shipyard bid pulls data from many departments (engineering, procurement, finance). Manually consolidating this from separate spreadsheets is slow and error-prone. The lack of integrated data can delay proposals and hide hidden costs.

How OAE Helps Shipyard Contractors

OAE was built to tackle these challenges head-on. Its platform turns chaotic bid data into a structured, collaborative process. For example, OAE’s built-in estimating calculators automate recurring tasks, like coating a hull or overhauling a generator, by applying formulas consistently.

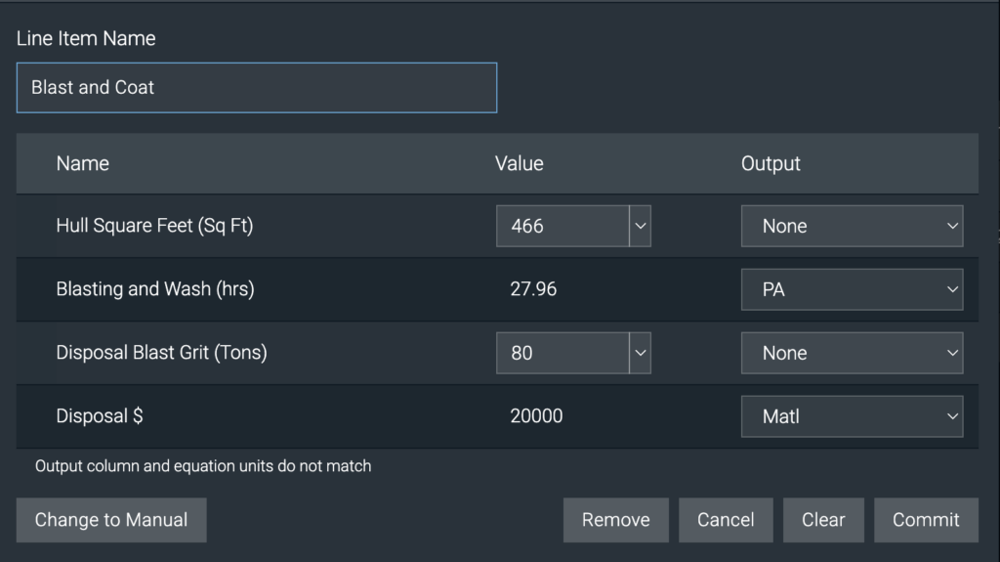

For example, OAE’s estimating interface lets you define custom calculators (here, a “Blast and Coat” work item) so inputs (hull square footage, grit disposal, etc.) automatically compute labor and material costs. This ensures each quote is consistent and traceable.

Key OAE Features that Help Maritime Projects

- Centralized Knowledge and Templates: OAE lets you build a library of reusable bid templates, line items, and calculators. Every past project, rate card, and estimator’s tip is captured in one place. Next time a similar ship overhaul comes up, you simply pull forward those elements – no re-guessing allowed. This library approach both speeds up bidding and preserves expert know-how.

- Real-Time Collaboration: Our multi-user platform means estimators, project managers, and even vetted subcontractors work on one live estimate together. Everyone sees the latest numbers. Built-in audit trails and comments mean no more email chains or lost spreadsheets. Any change is tracked, preventing the costly “version control” mistakes that plague manual bids.

- Multi-Year Project Modeling: For long contracts or phased deliveries, OAE supports multi-year estimates. You can assign rate cards, budget items, and reports either globally or per year, and let the system roll up totals automatically. This handles inflation and staged funding by design, so your bid can flex with time without manual recalculation.

- What-If Scenario Analysis: Worried about a sudden rise in steel prices or labor? OAE’s predictive analytics let you tweak inputs and instantly see effects on overall cost and margin. Testing “what-if” cases, for example, adding a 5% labor rate hike or swapping a part supplier, shows you trade-offs before you finalize the bid. This proactive insight helps lock in profitability even under uncertainty.

- Secure, Role-Based Access: You control who sees what. OAE’s permission system lets subcontractors fill in portions of the estimate without viewing your secret rates. Every user has a role (Estimator, Manager, etc.) with tailored rights.

- Seamless Data Integration: You can import old budget data or Excel sheets into OAE, and export finished estimates or reports out again. Attach blueprints and RFQs directly to line items. OAE’s flexible taxonomies let you tag projects by ship class, owner, or job type. All your data lives in one live system, eliminating manual cut-and-paste and giving you instant cross-project comparisons and dashboards.

By standardizing estimates and automating calculations, OAE turns estimating from a bottleneck into a strength. Estimators are free to focus on strategy (designing the work breakdown, ensuring compliance) while OAE handles the tedious math and organization.

Winning More Bids with OAE

The payoff is clear: more accurate bids, faster turnaround, and higher win rates. OAE helps improve its margins and wins big projects. Whether you work in commercial or naval shipyards, on new builds or repair/refit work, OAE’s platform adapts to your needs. It helps you escape the chaos of spreadsheets and bid smarter by leveraging every insight your team has..

With OAE, your proposals become data-driven and detail-oriented. The result is fewer cost overruns, better margin control, and a stronger reputation for reliability. In a tight market for shipyard work, that means winning more contracts and reducing hidden costs that eat into your profits.