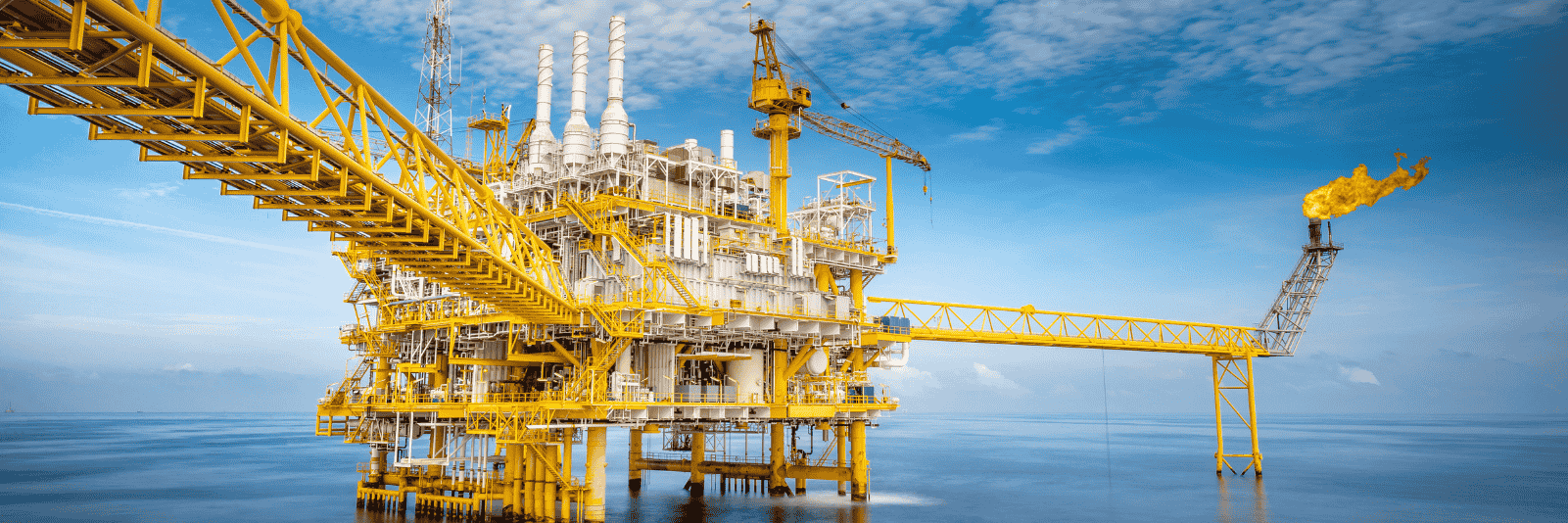

Maintenance, Repair, and Overhaul (MRO) in oil & gas covers all activities that keep wells, pipelines, refineries, platforms, and other assets in working order. In practice, this means everything from routine inspections and lubrication to major overhauls and emergency repairs. In oil & gas, this spans upstream (drilling rigs, subsea trees, wellheads), midstream (pumping stations, pipelines), and downstream (refineries, processing plants), including offshore platforms and FPSOs.

Why estimating MRO for oil & gas is especially challenging

Estimating MRO projects is challenging due to rapidly changing scopes (e.g., hidden defects discovered during disassembly), unpredictable demand for spare parts, and volatile logistics and lead times for specialized components. Limited skilled labor, certification requirements, and regulatory testing further complicate the process, often resulting in unforeseen costs and delays. Given the high consequences of downtime, building in conservative allowances and contingencies is essential for accurate estimates.

Top Cost Drivers and Project Cost Categories

In project management, costs are generally classified into five categories: direct, indirect, fixed, variable, and sunk costs. Direct costs are expenses directly tied to specific project activities, indirect costs represent overhead and support functions, fixed costs remain constant regardless of project scope, variable costs fluctuate with work volume, and sunk costs are past expenditures not recoverable for future decisions. Let’s examine the top oil and gas MRO cost drivers within these categories:

- Direct Costs: These are expenses tied directly to the work scope. In oil & gas MRO, the biggest line items are usually skilled labor (technicians, welders, electricians, offshore divers, pipeline crews, etc.). Experienced trades are essential and often drive the single largest share of the budget. Next are parts and materials – pumps, valves, pipes, electronics, and other spares are often engineered for harsh environments, low volume, and high quality, so they tend to be expensive. Direct costs also include equipment and tooling rentals (for example, cranes, pressure-test pumps, boats or ROVs, scaffolding or lifting frames needed to reach rig work-areas). Finally, many tasks are subcontracted, such as non-destructive inspections, specialty welding, hotwork permits, or flotation unit support; these subcontractor fees flow straight into the estimate.

- Indirect costs: These are overhead and support expenses. They include project management and administrative support (project managers, engineers, QA/QC staff, safety supervisors) and general site costs (power, utilities, campsite or yard facilities). Even when crews are on the job, salaries for planners/foremen and benefits or safety training costs are counted here. Another key indirect category is logistics and transportation. Moving crews, equipment, or parts – especially offshore – adds up quickly (e.g., helicopter flights, supply vessels, heavy-lift rigging). Customs, freight, and inland transport costs also belong here.

- Fixed Costs: These are fees that don’t vary with how much work is done. In offshore MRO, one fixed cost is often the platform or rig day-rate (or berth rental) – operators charge a flat fee per day for use of the facility or drydock, regardless of scope. Likewise, insurance or permit fees (well permits, environmental permits, standby vessels, etc.) are fixed once per campaign. A crucial fixed opportunity cost is downtime – any idle time for a production platform or pipeline means lost revenue. For example, studies show that each hour of unplanned downtime in oil & gas can cost millions of dollars in lost production.

- Variable Costs: These fluctuate with the scope and duration of work. The biggest items here are consumables (fuel, lubricants, solvents, welding rods, paint, oxygen/acetylene, chemicals for cleaning or flushing, etc.), which get used up in proportion to job size. Overtime and extra shifts are also variable – accelerating a job or working weekends incurs labor premiums. Finally, every MRO estimate needs a contingency buffer: hidden corrosion or cracked welding found during teardown often requires unplanned fixes. Contractors typically assign a percentage contingency for “just-in-case” repairs.

| Project Cost Category | Top Oil & Gas MRO Cost Factor |

| Direct Costs | • Skilled labor (technicians, engineers, specialists) • Materials & spare parts (pumps, valves, instrumentation) • Equipment rentals (cranes, scaffolding, testing equipment) • Subcontracted services (NDT, environmental, calibration) |

| Indirect Costs | • Project management & administration • Utilities & site support (power, water, security) |

| Fixed Costs | • Equipment downtime & lost production • Regulatory compliance & permits) |

| Variable Costs | • Consumables & supplies (lubricants, PPE, welding materials) • Contingency for unforeseen repairs |

| Sunk Costs | • Previously incurred expenses (prior studies, assessments) |

Putting it all together, the top 10 cost drivers in oil & gas MRO are: (1) skilled labor, (2) parts and materials, (3) equipment/tool rentals, (4) subcontractor services (all direct costs); (5) overhead/admin and (6) logistics (indirect costs); (7) platform/rig day-rates and (8) production downtime (fixed costs); and (9) consumables and (10) contingency allowance (variable costs). These elements usually account for virtually the entire MRO project budget.

Estimating Challenges for MRO Contractors

Putting together an accurate MRO estimate is notoriously hard. Below are some of the biggest headaches contractors face when pricing oil & gas maintenance:

- Uncertain Scope / Hidden Work: Many defects only surface during the job. For example, a routine inspection may uncover extensive corrosion, fatigue cracks, or gouged pipelines. In short, estimators often start with incomplete information. Every project is unique, and changes in one system can cascade. In oil & gas, those uncertainties are compounded by extreme conditions. As a result, contractors must guess at contingencies – too little and you run over budget, too much and you lose the bid.

- Supply Chain & Price Volatility: Specialized parts for oil & gas equipment can have long lead times. Pumps, turbo-machinery spares, and valves may come from a single manufacturer halfway around the world. If a part is backordered, the entire project halts. Recent global reports confirm that supply-chain snarls have become a major risk factor: missing a needed part can delay a project for weeks and sharply inflate labor and shipping costs. Commodity-driven price swings (steel, fuel, chemicals) also make material costs hard to pin down. Estimators must watch market trends and add price escalation clauses to be safe.

- Regulatory & Safety Compliance: Oil & gas is heavily regulated. Every well, platform, or refinery turnaround must meet strict safety and environmental standards (OSHA, EPA, API, class surveys, local laws, etc.). Estimators must budget for required inspections, certifications, flaring operations, waste handling, and extra safety measures. Missing a compliance item can mean rework or fines, so these costs are non-negotiable but hard to quantify upfront.

- Fragmented Tools and Knowledge Loss: Many MRO teams still prepare bids in Excel spreadsheets, emails, and PDFs. This patchwork approach breeds errors: formulas get copied wrong, version control gets lost, and important details (lessons learned from past jobs) vanish when key staff retire or move on. In practice, this means two identical-looking projects can end up wildly different on paper, simply because one estimator forgot a step. Ensuring completeness and consistency in the estimate is a constant battle without integrated estimating software.

These challenges mean that every MRO bid is a balancing act. Contractors must trust their best data and instincts, but even then, surprises are common. Using historical metrics and sound judgment is crucial, as is transparent communication with clients about uncertainties.

How OAE Helps Oil & Gas Contractors and Project Planners

OAE is specifically designed to address the complex estimation challenges facing oil and gas MRO contractors. Our advanced estimation platform enables teams to build more accurate bids faster while capturing and preserving critical organizational knowledge.

Knowledge Capture and Standardization: OAE allows senior estimators to encode their decades of experience into reusable templates, rate cards, and estimation libraries. This ensures that hard-won knowledge about equipment types, labor requirements, and material specifications becomes organizational assets rather than individual expertise that walks away when people retire.

Real-Time Collaboration: Our multi-user platform enables seamless collaboration between estimators, project managers, and subcontractors. Teams can work simultaneously on different project components while maintaining version control and eliminating lengthy email chains. Permission-based access ensures sensitive pricing data remains protected while allowing controlled collaboration.

Multi-Year Project Management: Unlike typical construction projects, oil and gas MRO often spans multiple years with varying phases and changing requirements. OAE handles complex project structures, allowing users to create time periods for multi-year projects and assign work items, rate cards, and reporting to specific phases or the entire project globally.

Advanced Rate Card Management: Oil and gas projects often require multiple pricing structures for different labor types, materials, and geographic locations. OAE supports multiple rate cards per project, customizable pricing structures, and flexible margin management to optimize profitability while remaining competitive.

Import and Export Capabilities: Recognizing that many organizations have valuable historical data in spreadsheets or legacy systems, OAE provides robust import capabilities to leverage existing information. Multiple export formats ensure compatibility with client requirements and downstream systems.

Security and Compliance: With NIST, CMMC, and ITAR compliance built in, OAE meets the stringent security requirements common in oil and gas operations. The platform can be hosted in your environment or deployed to meet specific security and compliance needs.

OAE’s specialized estimation platform addresses the unique challenges of oil and gas MRO, enabling contractors to capture their expert knowledge, collaborate effectively in real-time, and produce precise, reliable estimates. This translates to fewer costly surprises, improved project margins, and higher win rates on competitive MRO contracts.